HUITONG products including digger attachments, bucket, boom and stick. etc. HT Digger Bucket and Attachments including General-Purpose Bucket, Heavy-Duty Bucket, Thumb Bucket, Skeleton Bucket, Clamshell Bucket, Rake, Ripper, Grapple, Quick Coupler, Orange Peel Grab, Vibratory Hammer, Stone Concrete Pulverizer. etc. and HT Digger Boom and Arms including Excavator Telescopic Arm, Long Reach Boom, High Reach Demolition Boom, Standard Boom, Shortening Boom, Pilling Boom, Digger Extension. etc.

How to select those products in the market especially when small workshops get involved and offering supper "competitive price" ?

The quality of raw materials is one of the key factors affecting product quality. In addition, how to properly treat the raw materials (correct production procedure) is equally important.

We adopt all of our basic steels models, Q355B, Q550, Q690D, HG785. etc. from SCG, one of the top level steelmaker in China, with quality certifications, instead of the cheap stock stell plates on the market. Moreover, according to different steel models, thicknesses and welding methods, we’ve formulated reasonable ranges of welding current, voltage, welding speed, heating termperature. Etc. for our workers. Ensuring the products’ quality.

High-level accessories from qualified suppliers will boost the products' quality into a new level. When you purchased the products, you don't want to get into trouble with the products' outsourcing parts' quality issues. Because the factory wouldn't admit the problem and the period of getting the new accessories might take forever.

We’ve built a strict supplier audit system and adopt high-quality level accessories from qualified suppliers. Accessories including: anti-rust phosphating tubes to better protect the hydraulic system, self lubricanting cooper sets to protect the pivot point, Sumitomo high strength hoses, SANY after market cylinders. etc

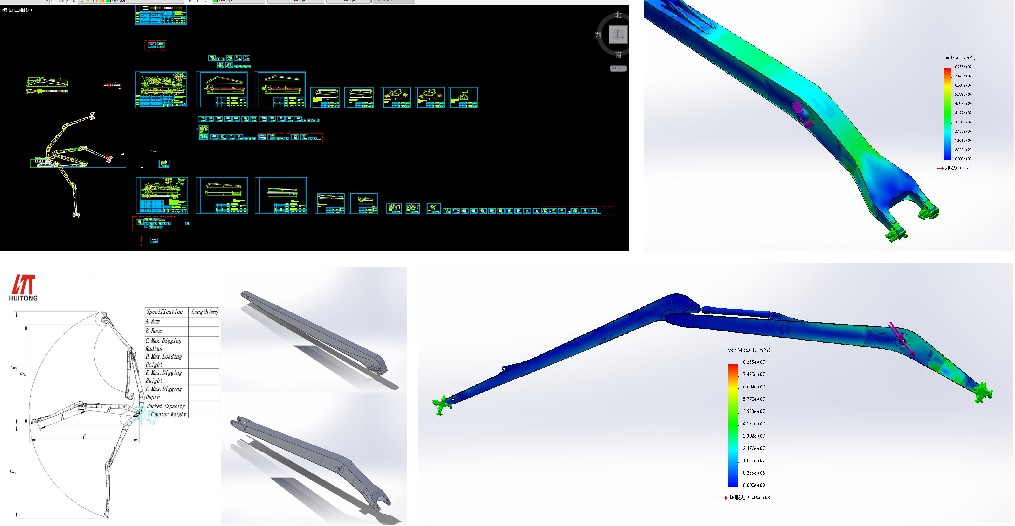

Our technical department will conduct FEA before manufacturing excavators above 50 tons. This ensures that the theoretical force range of the product is greater than the actual possible force range. At the same time, we customize the process standards according to different products to ensure the quality of the product during the processing. In addition, we accept any form of verification from customers.

HUITONG Machinery was established in 2011, and we aim for building long tearm relationships with customers. We believe that a good experience will make good story to tell. We truly operate our company according to ISO9001, ISO14001, ISO45001. And most of our products have obtained CE certification.

Moreover, We use a combination of manual assembly and automated welding to ensure the stability of welding quality and work efficiency. More importantly, the welding methods, current, voltage and output rate of different parts can be better controlled to ensure the overall quality of the product.

In addition, we use large double-sided boring machines to ensure the concentricity and parallelism of the product, so that the actual force direction of the product is consistent with the theoretical force direction to the greatest extent, thereby extending the service life of the product.

Furthermore, we use sandblasting equipment to remove the oxide layer on the surface of the product, increase the adhesion of the paint surface, and most importantly, eliminate the internal stress of the product caused by welding, reducing the quality problems that may occur in the product welds.

Last but not least, We use fully automatic pipe bending machines and welding machines, so that all the accessories on our products can be standardized and replicated. Customers can order accessories more easily through order numbers.

We are ready to show you what we got and we value quality just like you do.