HuiTong

HuiTong  2025-06-13

2025-06-13

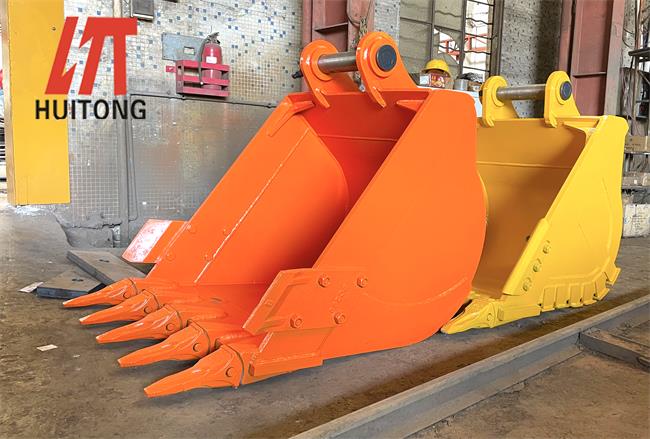

The excavator itself is a huge consumption of construction machinery and equipment, from daily maintenance to repair and maintenance to the replacement of spare parts, these are not small expenses. But some of these expenses must be something that everyone doesn't know what's going on. For example, the pin of the excavator arm and the pin of the excavator bucket were broken under normal use.

Have you ever experienced pin fractures when using excavator arms or buckets?

Many people must be wondering why their pin shafts are always broken and damaged without knowing the reason, which increases costs and causes considerable economic losses.

Maybe when you ask the sales manufacturer or your friends after you have a problem, the answer they give you may be that your operation is improper, or the quality of the pin you use is not good.

Here, Huitong wants to tell you that there is another reason for the pin fracture. This reason may be a small error in the production process of the excavator arm or bucket, which caused this situation in our use.

The excavator arm or bucket needs to be bored during production. The diameter of the boring determines whether the pin can be inserted smoothly. Many people may not be able to see the difference in boring size with the naked eye, because our boring accuracy unit is the unit of silk, which is a very small unit. But that is, this very small distance error is very likely to cause the pin to break when we use it.

Therefore, when we accept the product, we must check or ask the manufacturer to provide the tolerance range of the product. If the tolerance is too large, it may cause our pin shaft to break frequently.