HuiTong

HuiTong  2025-06-13

2025-06-13

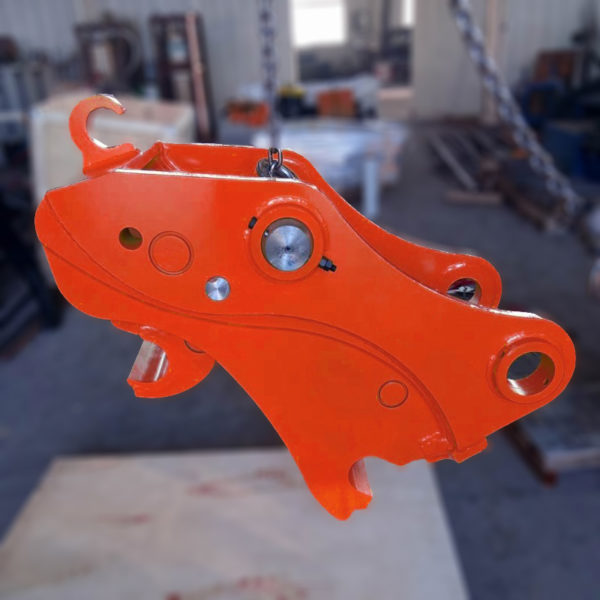

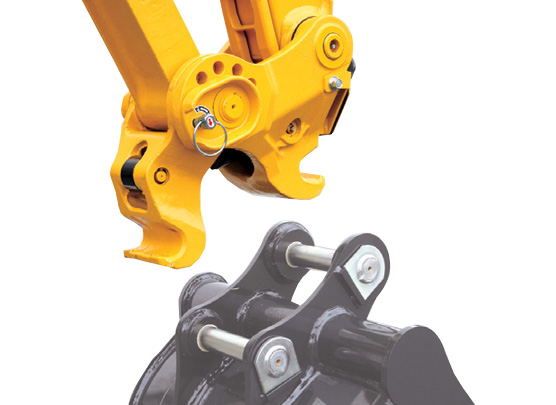

The excavator manual quick hitch is a structural product, which is composed of main body bracket, movable block, hydraulic cylinder, pin and other parts. Huitong compiled some small knowledge about the daily inspection and maintenance of excavator manual quick hitch and shared them with you.

Precautions for use and maintenance

1. When operating the excavator manual quick hitch, do not put your hands inside the machine, and do not touch the parts that can be turned with your hands. It's easy to get hurt

2. When disassembling and assembling the cylinder, be careful not to let impurities and moisture enter the cylinder.

3. Remove the dirt or impurities on the excavator manual quick hitch before performing lubrication and maintenance, and perform a maintenance every time the quick connector is used alternately five times. During maintenance, put butter into each grease nipple three times.

Note: *Please perform lubrication maintenance on the grappling hook twice a day.

4. In the operation of transporting concrete, concrete is easily adhered to the cylinder shaft and cylinder rod to make the two stick together. Therefore, the concrete must be cleaned after the operation.

Precautions for inspection and maintenance

A. Bolts: Check whether the bolts at the connection between the assembly shaft and the grapple shaft are loose, and there is no gap between the steel plates at the connection.

B. Cylinder: After every 120 hours of work, check whether the cylinder is damaged or leaks oil.

C. Pipelines: Pipelines must be installed when installing excavator manual quick hitch . After every 120 hours of work, be sure to check the pipeline for oil leakage and damage, as well as the connection.

D. Tiger mouth and grappling hook: After every 120 hours of work, check whether the connecting bucket or excavator accessories are worn, deformed, and whether there are cracks.

E. Check bolt caps: check bolts and bolt caps every 120 hours of work to make them firm and not loose to prevent accidents.

F. It is hoped that the cylinder rod can be kept free from impurities and damage. If it is not maintained, it will cause oil leakage in the cylinder.