HuiTong

HuiTong  2025-06-13

2025-06-13

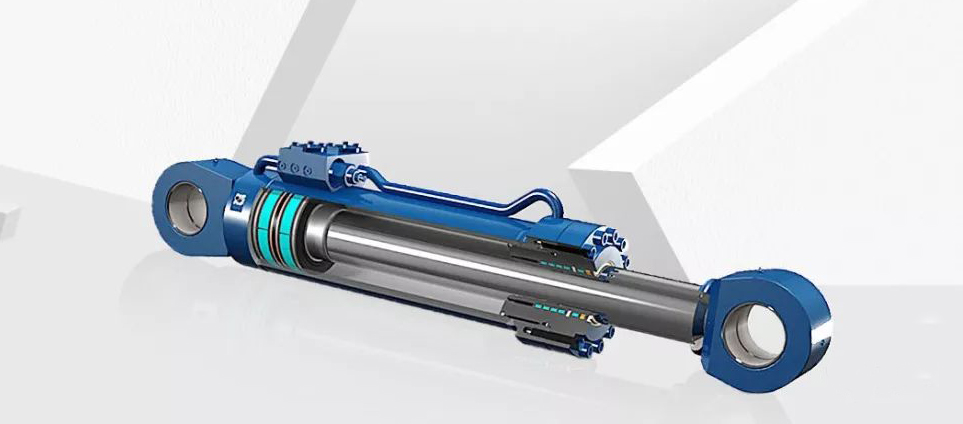

Excavator oil cylinder not working

The failure of the excavator oil cylinder to work is a "common problem" in summer. In the face of the soft oil cylinder, many owners have nothing to do. Although it is the off-season of construction, the owner can only work in a hurry when encountering urgent work.

In fact, there are many reasons for the failure of the cylinder to work. Even professional maintenance masters need to check step by step, so today the engineer will describe the maintenance process to you one by one. I hope that if you encounter such failures again, everyone can quickly and accurately solve the failure.

Fault phenomenon

When the excavator oil cylinder is weak, you should first operate the walking and slewing mechanism to observe whether these two actions are powerful. If the movement of the walking or slewing mechanism is normal and only the movement of the oil cylinder is weak, the analysis and inspection can be carried out in the following order.

Repair steps

(1) Check whether the pilot pressure of the control cylinder reversing valve is normal. If the pilot pressure is low, then from these three reasons: ① the pilot valve spring is broken, the spring should be replaced; ② the valve core is stuck or stuck, the valve core should be ground or foreign matter should be removed; ③ the oil port is blocked, foreign matter should be removed.

(2) If the pilot control oil pressure is normal, check whether the clearance between the valve stem and the valve hole of the multi-way reversing valve meets the requirements. If the matching gap between the valve stem and the ceramic hole of the multi-way reversing valve is too large, the internal leakage is large, part of the oil flow returns to the oil tank from the gap, the flow to the oil cylinder is reduced, and there is a certain pressure loss, the valve stem and the valve should be repaired separately. valve body.

(3) If the matching clearance between the valve stem and the valve hole meets the requirements, the pressure value can be measured at the oil inlet of the excavator oil cylinder. If the oil cylinder reaches the limit position and the overflow pressure value of the secondary relief valve is very low, the relief pressure value of the secondary relief valve can be increased; if the relief pressure value of the secondary relief valve cannot be adjusted to the rated value, the Repair or replace the secondary relief valve.

At this time, everyone should pay attention that if the pressure of the secondary relief valve is increased to the specified value and the pressure of the oil cylinder inlet is still very low, it may be caused by the high pressure cavity and the low pressure cavity in the multi-way reversing valve body. Damaged valve body. If the pressure at the oil inlet of the oil cylinder reaches the specified value of the relief pressure of the relief valve and the movement speed of the oil cylinder is still slow, the fault may occur inside the oil cylinder.

(4) The internal failure of the cylinder will cause the cylinder to move slowly. Internal faults include ①The piston seal is damaged or severely worn, and the internal leakage is large, and the piston seal should be replaced. ②The piston rod is slightly bent and should be repaired and corrected.

Summarize

In general, there are many failure points that can cause the excavator oil cylinder to work weakly, and it involves pressure testing, adjustment, replacement of related parts, etc. This is also the root cause of many owners who have tried to repair by themselves but failed.

Therefore, when encountering such tedious failure problems, the first point is to accurately judge the failure phenomenon, and the second point is to patiently disassemble, assemble, and clean up the failure points one by one until the failure problem is completely solved.