HuiTong

HuiTong  2025-06-13

2025-06-13

Before we gave you a rough introduction to our hydraulic quick hitch for mini excavator. After so many years of development and improvement, the hydraulic quick hitch for mini excavator have also undergone two generations of improvements. So today we will talk about some special classics in the next-generation hydraulic quick hitch for mini excavator. The style also allows everyone to know more about the quick-change fittings and to know their needs more clearly when purchasing.

The first thing to talk about is the manual quick-change coupling in the first generation of quick-change couplings

Although the connection method of manual quick-change coupling is more convenient and quicker than the method of directly connecting the attachment to the stick, the replacement process of the attachment is still relatively time-consuming, requiring the operator to come out of the cockpit to operate and install the safety lock pin .

In addition, due to the limited manual unlocking force when disassembling the machine tool, the designed locking spring force should not be too large, which easily leads to insufficient locking force of the lock hook, resulting in the accident of loose coupling or even falling off of the accessory machine tool.

The second type is semi-automatic quick-change couplings, which are divided into semi-automatic quick-change couplings and lock hook type devices:

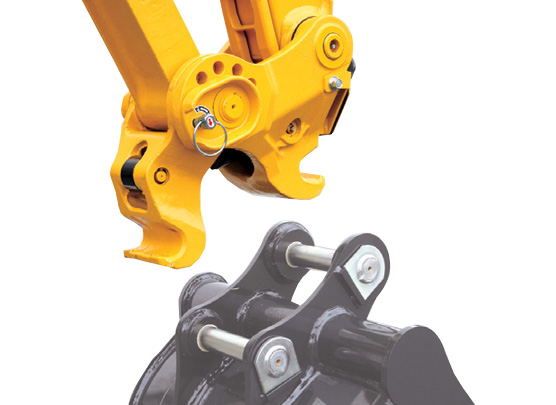

Among them, the lock hook type device of the semi-automatic quick change joint adopts the form of front and rear lock hooks (usually the rear lock hook is movable) to realize the connection with the auxiliary equipment. The piston-type oil cylinder pushes the lock pin mechanism to the dead center position to complete the connection and lock of the attachment.

The lock hook type semi-automatic quick-change joint uses a hydraulic control valve that can be manipulated in the cab to control the piston rod of the hydraulic cylinder to drive the guide block connected to it, push the double lock pin mechanism, and insert the lock pin into the lock pin hole to complete the property. The connection of the tool is locked. However, because the distance between the center holes of the two pins is fixed and not adjustable, the versatility of this type of quick change device is limited to a certain extent.

The convenience of replacing attachments with semi-automatic quick-change couplings is obviously better than that of manual quick-change couplings. However, like manual quick-change couplings, after the semi-automatic quick-change couplings complete the connection with the attachment, the operator needs to manually insert the safety plug from the side. To ensure that the locking mechanism is in a closed state, and to prevent the locking cylinder from retracting due to misoperation and failure of the hydraulic system during the operation, resulting in an attachment falling off accident.

However, in engineering practice, there may indeed be safety accidents in which the operator forgets to insert the safety pin to lock the joint and causes a mistake.

The last one is the ordinary automatic quick change joint, the same is also divided into single hook locking type and double hook locking type

The fixed front lock hook is combined with the front pin of the bucket, and the movable rear lock hook is driven by a hydraulic cylinder and combined with the rear pin of the bucket, using gravity to lock the lever (the dead center position of the four-bar mechanism) or other methods Realize automatic locking.

The double-claw lock type automatic quick-change joint is additionally designed with a coupled movable front lock hook, which is combined with the front pin of the bucket and locked in the exact position by a gravity device or other means

Compared with manual mechanical and semi-automatic quick-change couplings, the fully-automatic quick-change device can be used by the operator in the cockpit to complete machine tool replacement and safe locking, which is quick, fast, safe and reliable.

It should be noted that during use: the safety latch mechanism of the automatic quick-change connector needs regular inspection and maintenance to ensure the normal operation of the locking mechanism.

The above three types of hydraulic quick hitch for mini excavator basically represent the first generation of hydraulic quick hitch for mini excavator, and are currently the leading products in the market for quick-change applications. There are more than 20 varieties, occupying more than 90% of the market share.

Different brands of products have different structural characteristics in terms of body structure design, lock hooks, safety devices, etc. Therefore, the products have their own characteristics in terms of versatility and applicability to different machines, safety during use, and the degree of automation of replacement. Features.