HuiTong

HuiTong  2025-06-13

2025-06-13

ACTION

When evaluating the safety management of excavator hydraulic quick coupler, inspectors should consider the following questions:

· If the excavator hydraulic quick coupler to the excavator under its control requires a manual safety pin, please contact the site supervisor.

· Does the risk assessment cover the risk of bucket separation?

· In addition to demonstrating the operation of well-trained excavators, are excavator operators trained in the use of excavator hydraulic quick coupler and (if applicable) the use of excavators as cranes? .

·Does the excavator be inspected and repaired in the cab every day? Does it include a checklist? Does the checklist include QH and lubrication checks? Is there a record of actual inspection and maintenance performed?

· Which management systems must they check whether the manual safety pins are still in place?

· If the safety pin is inserted in the correct position.

· Can the operator explain the type of quick coupling system he has, and is there a manual or instruction card in the cab?

·Does the operator know how to visually check whether the excavator hydraulic quick coupler is locked?

·Does the operator know that for all types of quick couplings, the bucket must be tested for safety after the bucket is replaced?

If the inspector suspects that the quick connector is faulty or missing parts, the following methods can be used to prove it:

Hydraulic locking and bending

· Any apparently missing or damaged parts; or

· The hydraulic hose near the hook is severely damaged.

Quick hook system

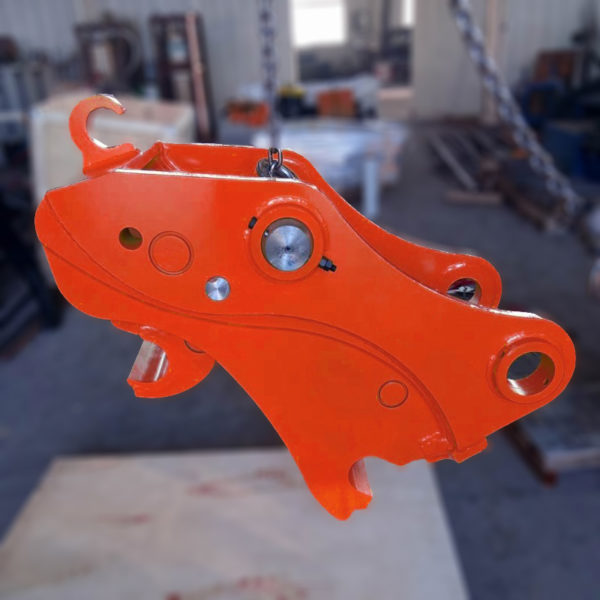

Excavator hydraulic quick coupler on the market can be manual or non-manual. Non-manual systems are called semi-automatic and automatic systems:

1. The manual system requires the operator to open and close the latch, for example by winding a helix, or using a joystick to open a spring-loaded latch to change the bucket. Although faster than the traditional bucket replacement method, this method is relatively slow and cannot be performed through the excavator's cab.

2. The non-manual system uses a hydraulic piston to move the latch to secure the bucket.

The semi-automatic system forces the operator to leave the cab to improve safety after activating the latch of the quick connector of the excavator and inserting the fixing pin into the hook. The pin usually works by locking the latch in its closed position. This is often referred to as a "safety bar" rather than the load-bearing part of the hook. The safety pin can only be inserted when the latch is in the fully closed position.

Automatic systems can usually be fully operated from the cab, usually with an independent locking system, which can operate automatically and can keep the lock in the closed position without relying on hydraulic pressure. The automated system must use a method that allows the operator to verify that the hook has been locked from the cab, for example, when unlocked, the locking pin may protrude from the side of the hook. Large accessories such as rammers may prevent the lock status from being verified from the cab, in which case the operator must leave the cab to check the lock status.

Excavator hydraulic quick coupler are becoming more and more common, and now many large excavators and some small excavators are equipped with excavator hydraulic quick coupler. Excavator hydraulic quick coupler require maintenance and may need to be replaced during the life of the excavator. If it has been replaced, it is important that the control must be compatible with the new hook or be replaced at the same time.

Although accidents occurred using the excavator hydraulic quick coupler, accident statistics show that most accidents occurred on semi-automatic systems where manual safety pins should be inserted, but the operator did not successfully insert them.