HuiTong

HuiTong  2025-06-13

2025-06-13

Advantages of solid inlaid self-lubricating bearings

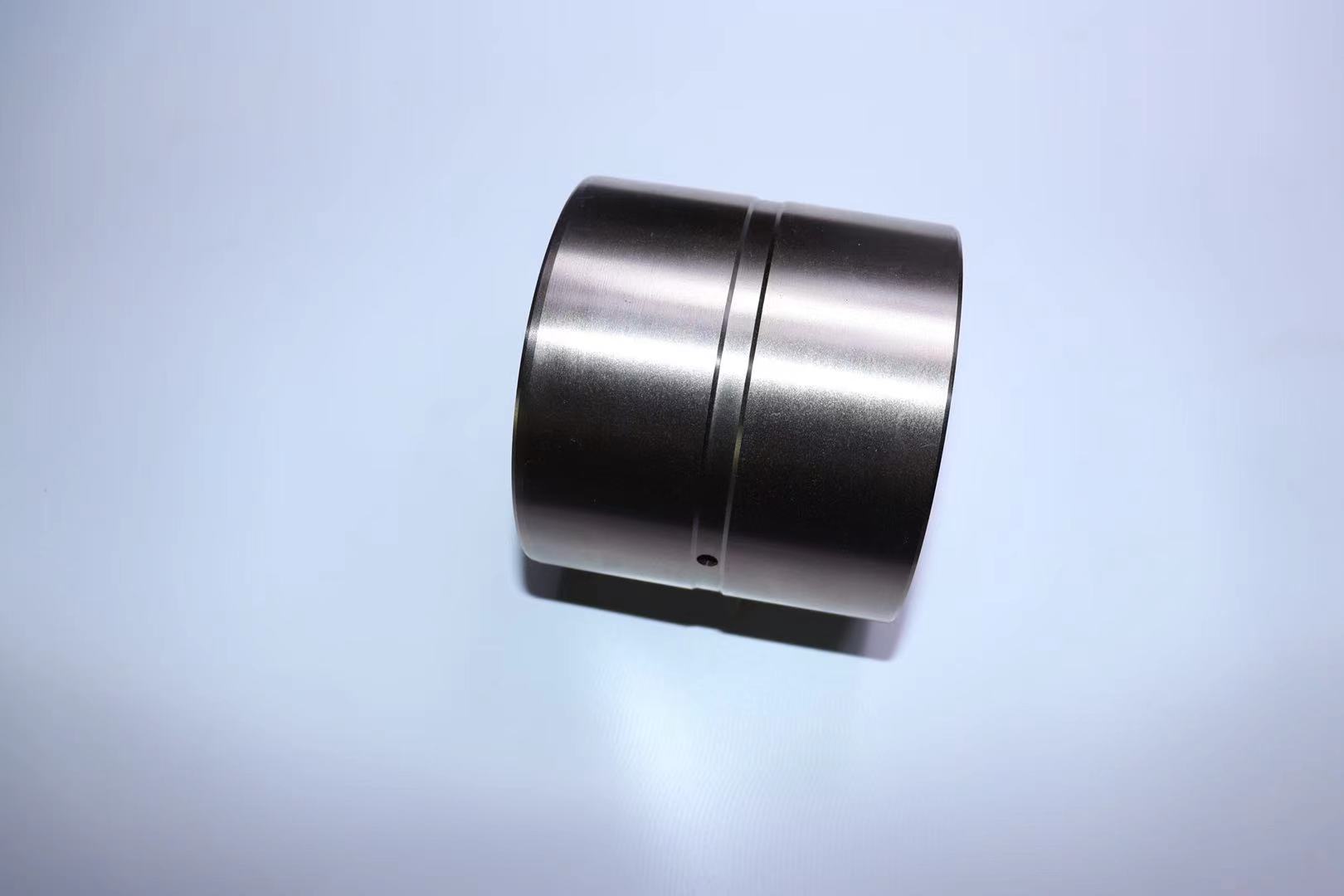

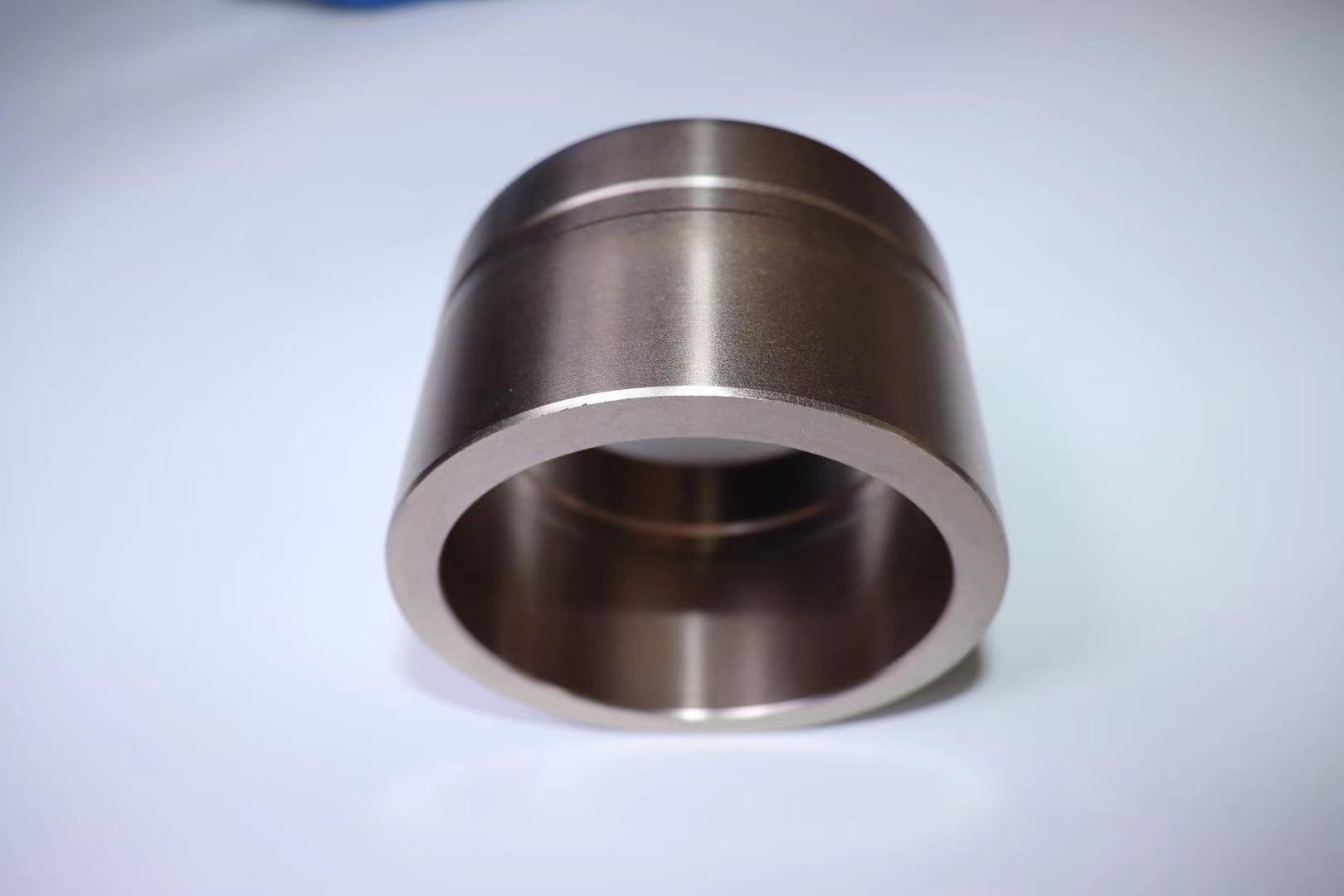

The solid-inlaid self-lubricating bearings opens holes of appropriate size and orderly arrangement on the metal friction surface of the bearing matrix, and then embeds the molded solid lubricant with unique lubricating properties in the holes (the area of the solid lubricant is generally 25% of the friction area -35%) and made of self-lubricating bearings.

The bearing combines the respective advantages of the metal matrix and the specially formulated lubricating material, breaking through the limitations of general bearings that rely on oil film lubrication. RCB solid-inlaid self-lubricating bearings are especially suitable for use under special conditions of oil-free, high temperature, high load, low speed, anti-fouling, anti-corrosion, anti-radiation, and in water or vacuum solution infiltration and no lubricant film can be added.

In the choice of the base material of the self-lubricating bearing (graphite copper sleeve), according to the main failure mode of the bearing, combined with the harsh and changeable characteristics of the construction machinery use environment, and comprehensively considering factors such as material strength, corrosion resistance and adaptability, select solid The base material of the self-lubricating bearing is high-strength brass with high load-bearing capacity. Its allowable static load-bearing capacity is 250N/mmi, which can be used for low-speed dynamic load-bearing capacity of 100N/mm' and has good wear resistance.

The application of self-lubricating bearings (graphite copper sleeve) in excavators effectively simplifies the mechanical design, and its structure is simple, the manufacturability is good, the maintenance cost of the machine is reduced, the quality is reliable, and it is helpful to improve the work of the whole machine reliability. At the same time, the solid self-lubricating bearing has superior performance in use and strong product competitiveness. It will be more fully applied in the use of construction machinery in the future.