HuiTong

HuiTong  2025-06-13

2025-06-13

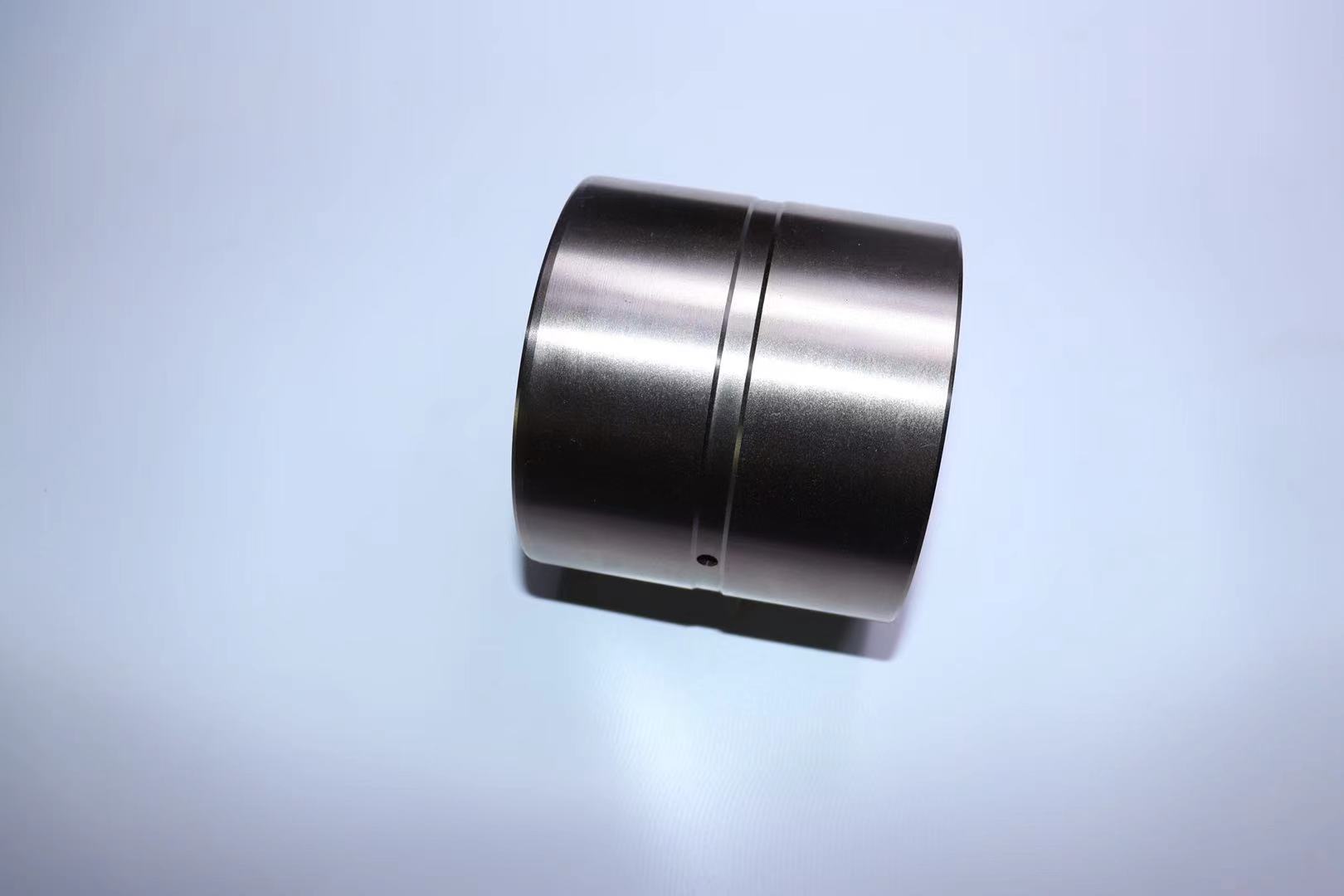

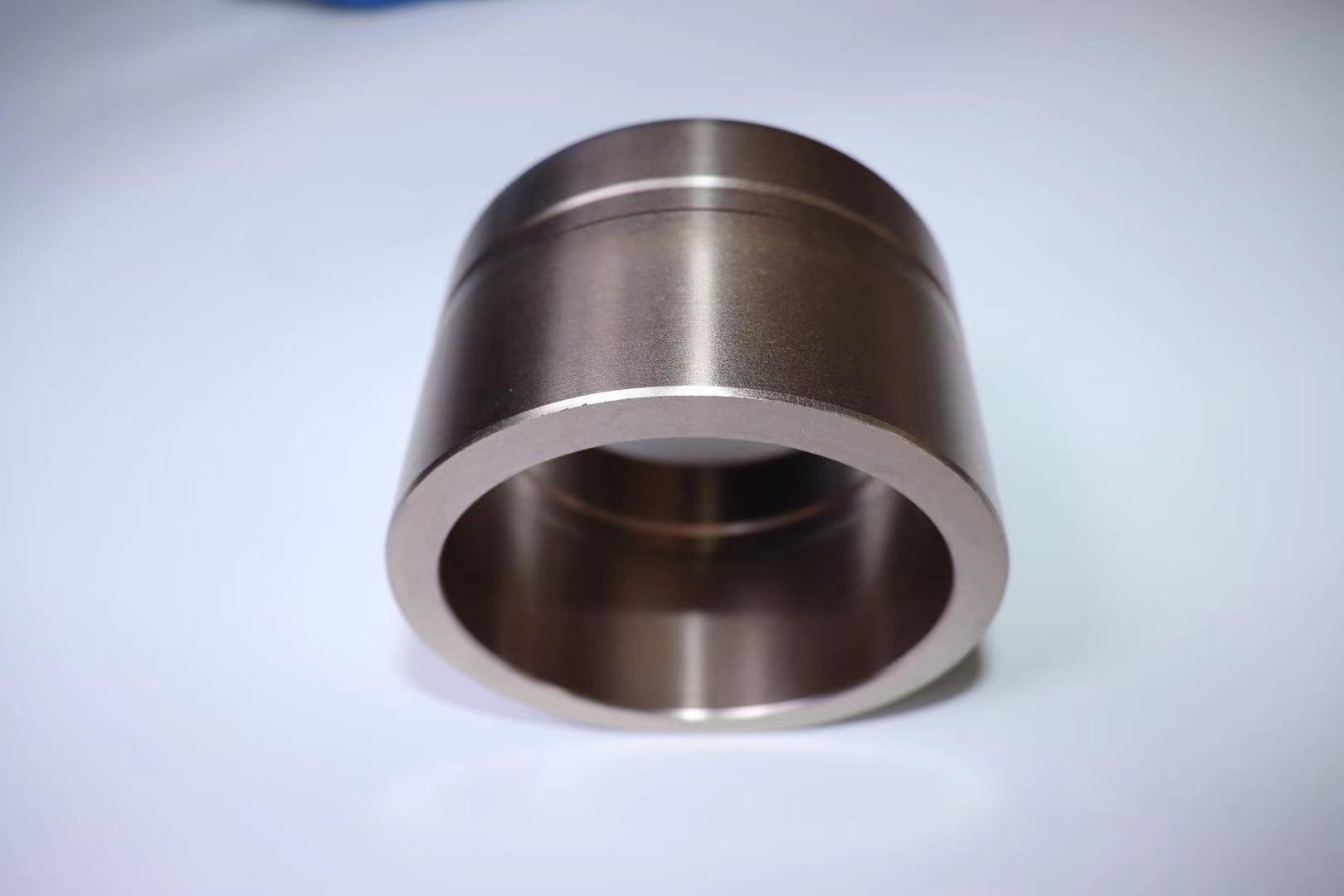

1. The oil-impregnated bushings is a combination of metal powder and has a structural gap of 10-40%; the embedded self-lubricating bearing matrix is made of centrifugal casting; the density of the matrix is relatively high, the bonding strength is higher than that of the oil-impregnated bushings, and the service life is longer than that of the oil-impregnated bearing to be long.

2. The lubricating material of the oil-containing bushings is lubricating oil, and the oil film has enough thickness to eliminate the direct contact between the two friction surfaces. At this time, there is only friction between liquid molecules, so the coefficient of friction is very small (f = 0.001 to 0.008), which significantly reduces friction and wear; while the lubricating material of the inlaid self-lubricating bearing is solid lubricating material, even in the absence of oil Under working conditions, the good lubrication effect can still be removed, which can ensure the uninterrupted and sustainable lubrication, and its effective lubrication life is consistent with the life of the substrate;

3. The lubricating oil in the oil-containing bushings is volatile and easy to lose. The lubricating oil film loses faster under high temperature and high pressure, and cannot obtain the proper lubrication effect; while in the graphite copper sleeve, the solid lubricant is rubbed by the solid in the hole or groove. The lubricant is transferred or reversely transferred to the friction surface, and a solid transfer film with good lubrication, firm adhesion and uniform coverage is formed on the friction surface, which greatly reduces friction and wear. As the friction progresses, the embedded solid lubricant is continuously provided on the friction surface, ensuring good lubrication of the friction pair during long-term operation.