HuiTong

HuiTong  2025-06-13

2025-06-13

Bearings are used to support components, and are also used to support the rotating parts on the shaft. The types of bushings are classified according to the nature of friction: sliding bearings and rolling bearings; according to the direction of load: radial bearings, push bearings, and centripetal thrust Bearings, etc.

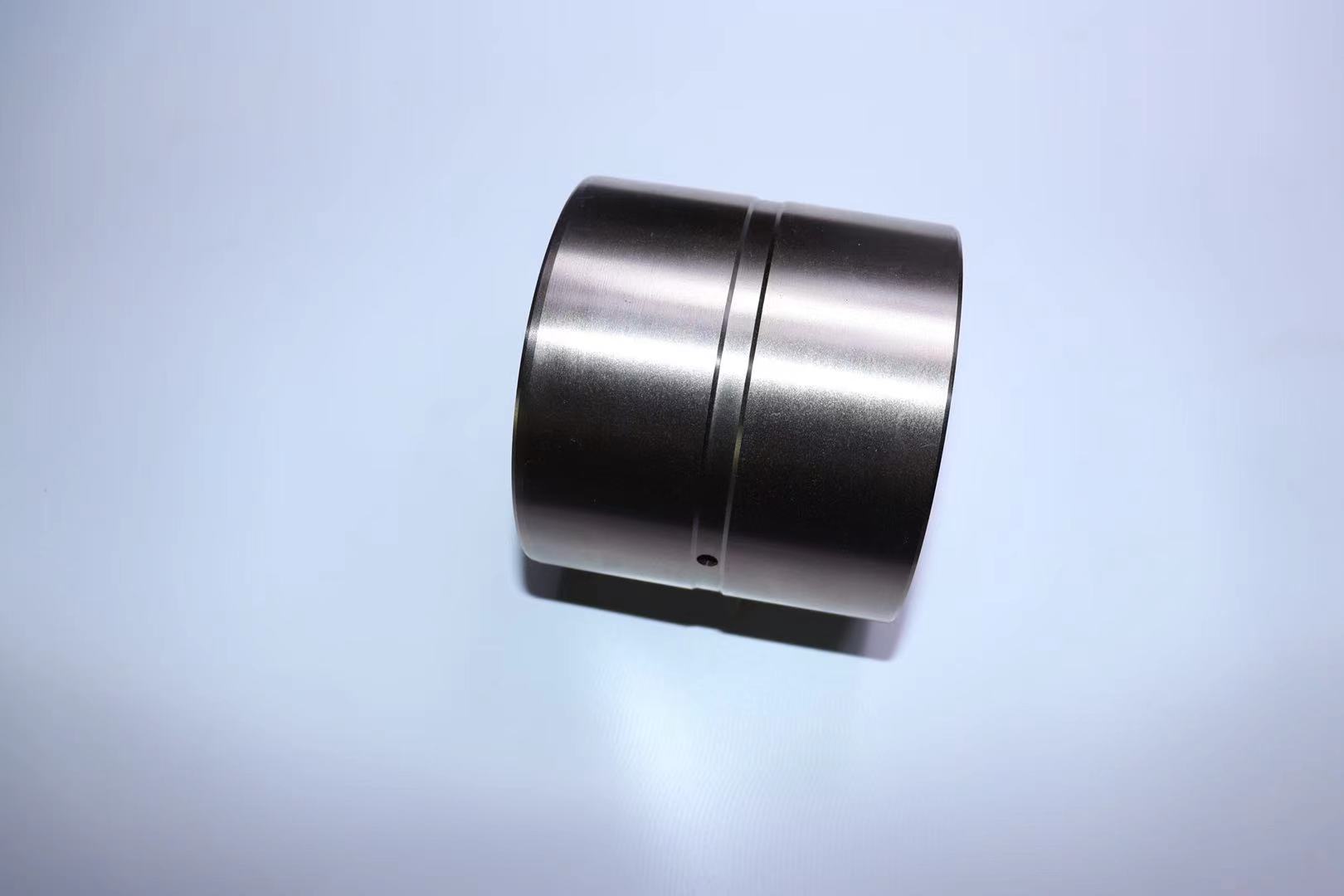

1 Excavator oil bushings

Oil-impregnated bushings use metal powder as the main raw material, and the sintered body produced by powder metallurgy is inherently porous, and has the technical advantages of freely adjusting the number, size, shape and distribution of pores during the manufacturing process. Using the porosity of the sintered body, it is impregnated with 10%-40% (volume fraction) of lubricating oil and used in the state of self-lubricating. During operation, the temperature of the bearing rises. Since the expansion coefficient of oil is larger than that of metal, it automatically enters the sliding surface to lubricate the bearing. Oil-impregnated bearings can be used for a long time by adding oil once, and are often used in occasions where it is inconvenient to add oil.

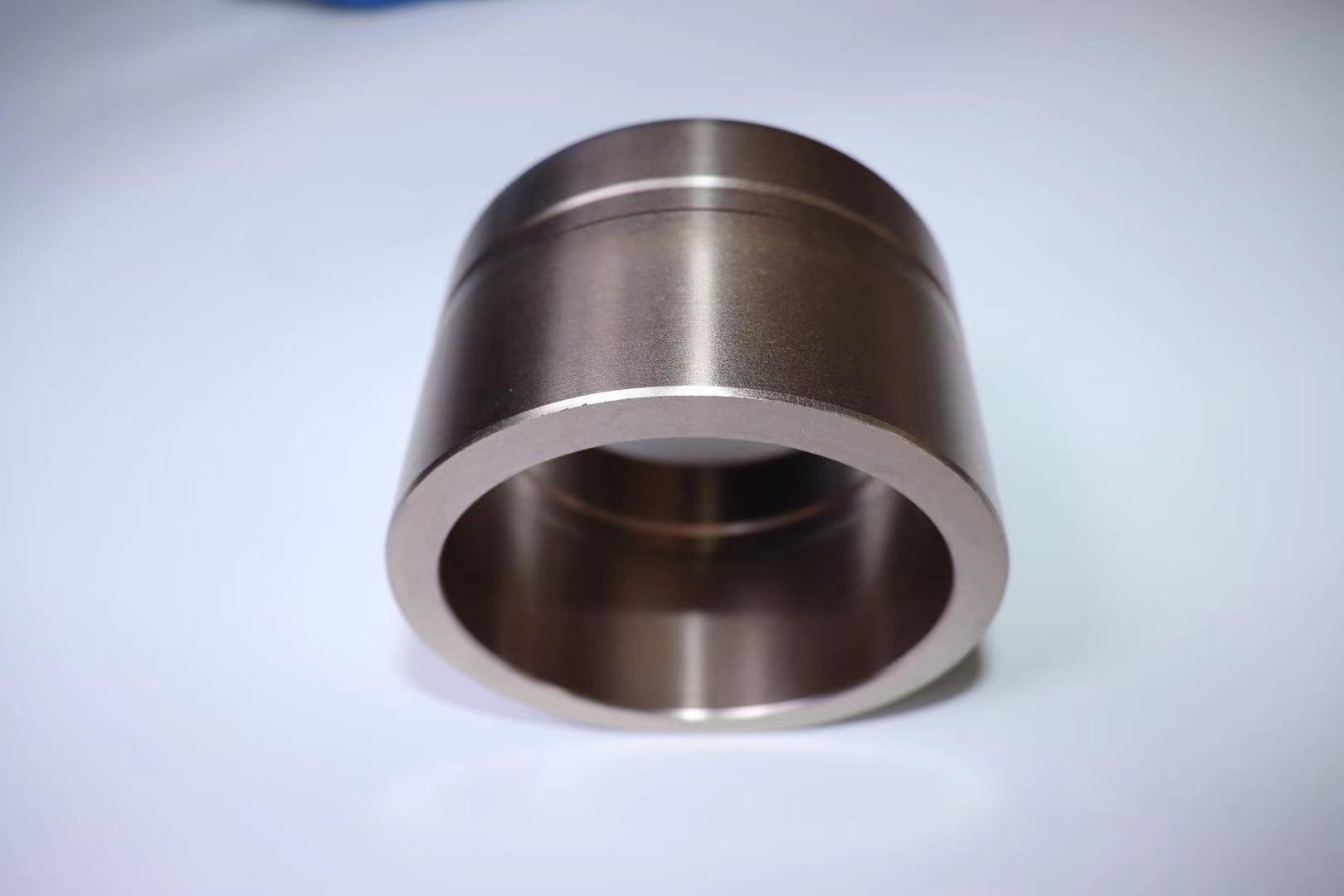

2 Solid-inlaid self-lubricating bushings for excavators

The metal-based inlaid solid self-lubricating bushings is a novel lubricating bearing that combines the characteristics of metal bearings and self-lubricating bearings. The metal matrix bears the load, and the specially formulated solid lubricating material plays the role of lubrication. It has the characteristics of high carrying capacity, impact resistance, high temperature resistance, and strong self-lubricating ability. It is especially suitable for heavy loads, low speeds, reciprocating or swinging situations where it is difficult to lubricate and form an oil film, and it is not afraid of water wash and other acid erosion. And scour. Inlaid bearings not only save oil and energy, but also have a longer working life than ordinary sliding bearings. At present, the products have been widely used in metallurgical continuous casting machines, steel rolling equipment, mining machinery, ships, steam turbines, water turbines, injection molding machines and equipment production lines.