Excavator extension boom have been widely used in large-scale civil engineering fields and construction projects in recent years. Because of their high-efficiency performance, they are widely loved by users. They have given great help in engineering operations and saved A lot of construction time reduces the difficulty of construction.But most users only know how to use it, but few people know how the extended boom is made, and many people are curious about how such a big guy is made. Today, I will give you a brief introduction to the production process of the excavator extension boom.

The production of the extension arm of the excavator:

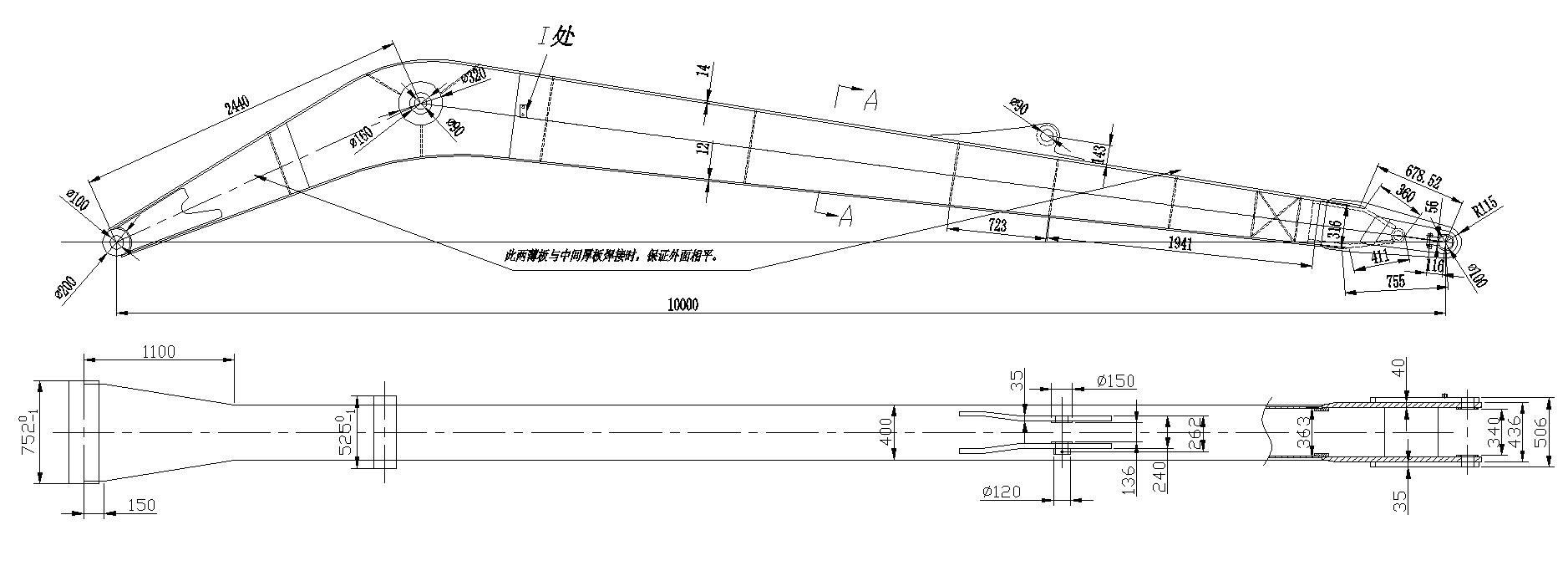

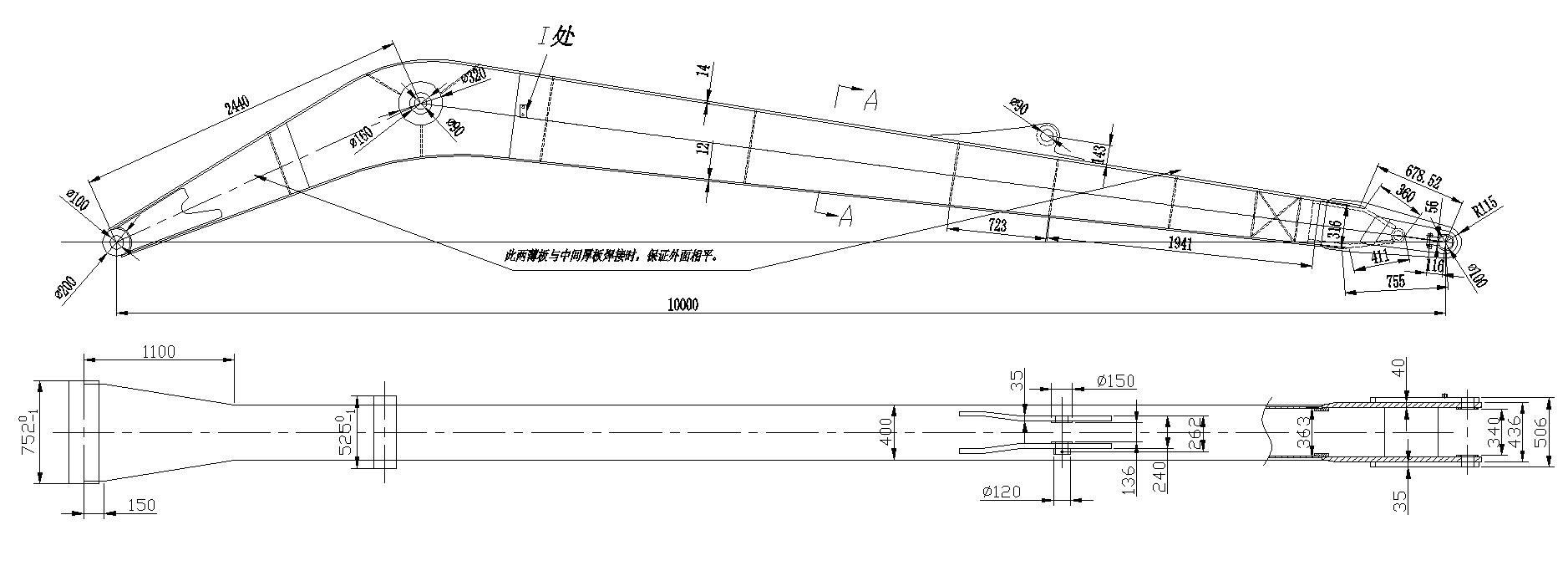

- At the beginning, we will design products, conduct stress analysis and simulate actions by engineering designers through 3D auxiliary design software and systems such as SOLOD WORKS, Creo Parametric, and CAD according to the needs of users. Draw detailed engineering drawings and submit them to the production workshop.

- The production workshop uses CNC cutting to cut the material according to the engineering drawings, and then uses the bending machine for bending and shaping. After cutting all processed materials, hand them over to professional technicians for welding operations.

- The main semi-finished product of the extension arm of the excavator is completed after a long time of welding by professional welding technicians, and the boring operation is carried out after passing the quality inspection.

- After the boring operation, install the extension boom base and pipeline, and carry out acid washing and phosphating treatment on the hydraulic pipeline to clean the pipeline to ensure that the pipeline is clean. So far, the semi-finished product of the extended boom has also been completed.

- Carry out stress resistance test on the semi-finished product of the extension arm. After the test, the product is shot blasted, and the rough surface of the product is polished with high gloss.

- The extended arm after shot blasting will enter the spraying workshop for high-temperature spraying, and the product will be anti-oxidation and appearance spraying paint.

- Carry out the last pre-show inspection on the extended boom that has been sprayed and painted.

- The last qualified extension boom will leave the factory.

After the above series of complex procedures, the entire excavator's extension boom is manufactured. In order to ensure the safety performance of products, professional quality inspectors will conduct random inspections and check on product quality to ensure the reliability and safety of product quality.

HuiTong

HuiTong  2025-06-13

2025-06-13