HuiTong

HuiTong  2025-06-13

2025-06-13

Many excavator drivers must know that many engineering projects can not solve everything with a bucket. According to different engineering projects, using different attachments can achieve half the result with half the effort. In some projects that need to be demolished, the excavator ripper bucket is a targeted tool.

The excavator ripper bucket with strong excavation and cutting force, and the replaceable working device with the functions of excavation, crushing and loosening. Applicable working conditions include: excavation of asphalt pavement, hard soil, sub-hard rock, weathered stone, frozen soil, and can also be used to excavate cracked rocks.

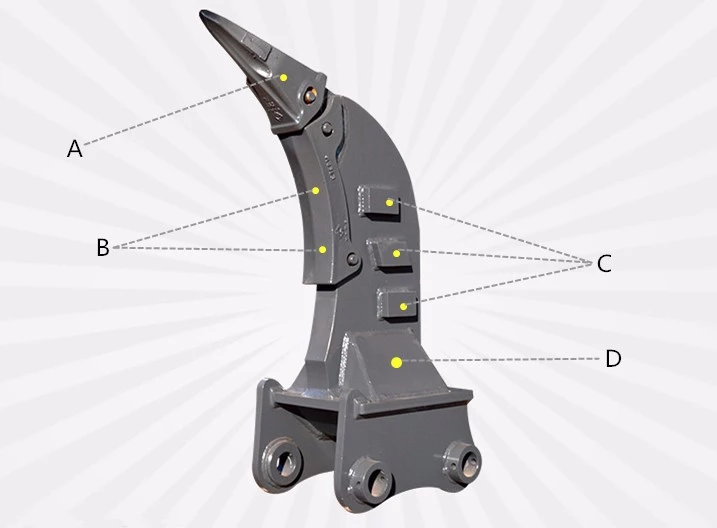

The excavator ripper bucket is composed of a main board, an ear plate, an ear seat plate, bucket ears, bucket teeth, reinforcement plates and other components. Huitong Machinery usually chooses different special steels according to the working conditions to improve the efficiency and durability of the products.

Excavator ripper bucket are usually designed in an arc shape, mainly because the arc is not easy to deform under the action of external force and has good stability. Depending on the arm length of various models, the radius of this arc is also different. Because the tooth tip and the main board are arc-shaped, it is easier for the bucket teeth to be introduced into the main board into the ground for destruction.

Material aspect

Nowadays, due to the poor market environment and fierce competition, customers are mostly considering price when purchasing, so the market is full of shoddy manufacturers. Take the material, which is better, ordinary steel plate or wear-resistant manganese steel plate? Most conscientious manufacturers have strict requirements on the material, and the material determines the service life. Although the wear-resistant manganese steel plate with alloy elements can be more expensive, the failure rate in the later use process is low, and it is not easy to break and has a long life, so since you want to buy , Don’t care about the price difference of one thousand or eight hundred yuan, after all, you get what you pay for; the ripper made by HUITONG Machinery is made of high-quality high-manganese low-carbon alloy steel Q345B, which has high hardness, high strength and wear resistance, and a longer service life. long.

Sheet thickness

The same ripper, but the thickness of the steel plate used by each manufacturer is different, the thickness determines the weight, and the weight determines everything, you know! Needless to say!

Welding process

After years of experience accumulation, large regular manufacturers have matured the welding process. Welding flaw detection, shot blasting, and quality inspection are very strict. In the later use, the defect-free welding ensures that the failure rate is very low and the strength is high. The sand ensures that the ripper is not easy to rust and oxidize during long-term storage!

Design process

After years of exploration, regular old manufacturers have gradually matured in product design. The curvature of the hook is just in line with the stress point of the construction. The dispersion of torque makes the ripper stronger. Many manufacturers weld a guard plate in the middle of the hook. It seems tall and can be very wearable! In fact, from a professional point of view, the fewer welding points of the ripper, the better. During the construction process, the fracture often cracks from the welding point of the protective plate. The welding is equivalent to annealing the steel plate, and the stress is concentrated, which is more prone to fracture failure.

If you can fully consider the above points when buying a excavator ripper bucket, I believe you will not suffer anymore when buying it. Of course, if you still have any confusion, you can contact us directly, we can analyze for you and give a reasonable opinion.