HuiTong

HuiTong  2025-06-13

2025-06-13

We have receiving many counsulting from our customers about our new designed 2 Section Rock Boom, so called "the ripper boom". I will explain the difference of those two types of Rock Boom in this article.

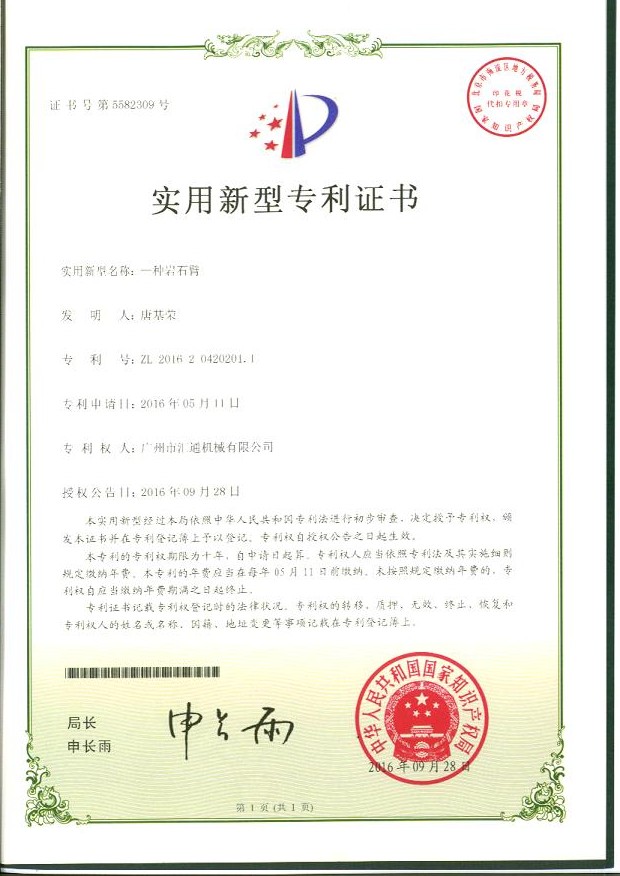

Huitong New Designed Rock Boom is a Epoch-making product in the market and we've gained the patent from the government and are few of the manufacturer that officially allowed to manufacture this product.

1. The arm is formed by one piece of high-strength manganese steel, which reduces welding and processing and making it tougher.

2. The front end is welded with replaceable D11 Diamond Bucket Tooth, which ensure a more stable and sturdy quality.

3. The boom is no longer a solid boom, instead, it's a hallow reinforced boom, which reduces the weight greatly and reduces the overall performance loss of the excavator.

4. The innovative design of the integrated rock arm integrates the oil paths of the bucket cylinder and the stick cylinder into the pipeline of the stick cylinder, increasing the overall oil flow of the stick cylinder and increasing the strength and speed of the stick cylinder without changing the overall setting of the excavators' hydraulic system.

5. The plate thickness of the arm reaches to 30cm (12 inches), which can adapt to more severe working conditions and avoiding quality problems and increase the service life of the product.

Firstly, the three section rock boom is more flexible because it has one more movement than the new designed rock boom, but the bucket cylinder of the arm only played a supporting role and moved very little, which lower it's strength. And when it digs rock with high hardness, it has very low working efficiency.

On the countrary, the new designed rock boom eliminates the bucket cylinder, and the arm and ripper are connected in one piece, subcerting the original way of working. Although some flexibility is sacrificed, it completely solves the "lack of strength" problem.

Secondly, by canceling the bucket cylinder and connecting the oil pipe of the bucket cylinder to the stick cylinder, the driver of the excavator could operate the machine more easily, and also the ripper and connecting rod were canceled, which lower its maintenance cost.

On the countrary, with the bucket cylinder being added, the 3 section rock boom has one more movement, but the problem is that this movement of the front ripper is very limited. Most of the driver wouldn't use it in most of the time. That's also the reason why we redesigned it.

Thirdly, in terms of working principle of the equipment, both the traditional rock boom and the integrated boom increase it's destructive power of the ripper by increasing the weight of the Boom. In another words, the heavier the stronger. The weight of the 3 section rock boom is been added mostly on the Boom instead of the arm, which transfereed to the body of the machine instead of the object. And the weight of the new type boom is been added mostly on the Arm, which increase it's breaking power to the object.

All in all, if you were dealing with severe working condition, the new designed 2 Section Rock Boom will be our recommendation. Even tough it has higher price, it's totally worthy, told by many of the customers.