HuiTong

HuiTong  2025-06-13

2025-06-13

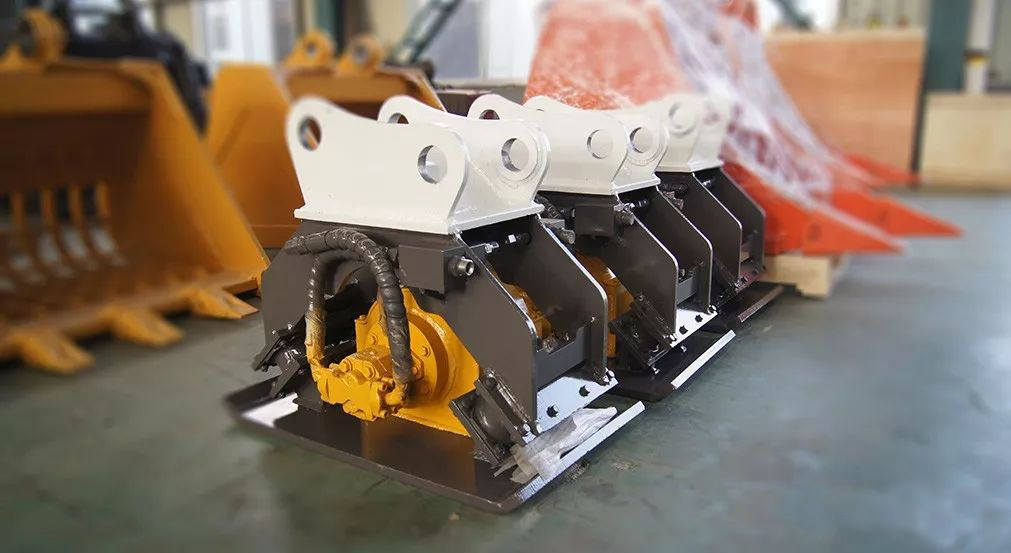

The excavator compactor vibratory roller is composed of a hydraulic motor, an eccentric mechanism, and a tamper plate. The hydraulic rammer uses the hydraulic motor to drive the eccentric mechanism to rotate, and the vibration generated by the rotation acts on the rammed material through the tamper plate to make it compact. Excavator compactor vibratory roller has the characteristics of light weight, convenience, flexibility and good compaction effect. It is mainly used in the compaction of slopes, dams and building foundations. It is mainly used by excavators, which can be adapted to 5 tons to 32 tons of excavators.

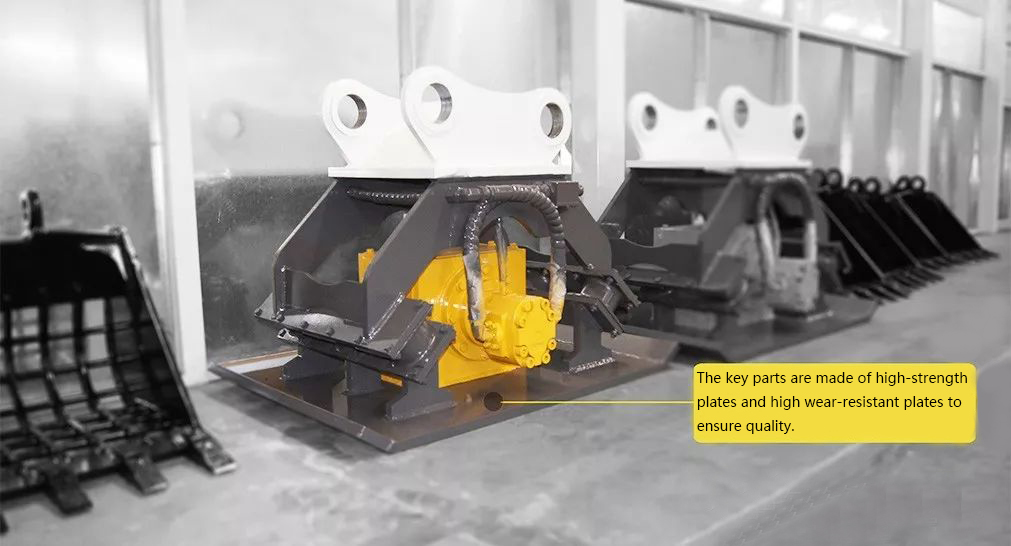

Matters needing attention when purchasing a excavator compactor vibratory roller:

1. First of all, pay attention to whether its motor is imported, which is related to its use effect and life;

2. The area of the rammer plate, the larger the area of the rammer plate, the better. If the motor is too large, it will easily increase the failure rate. If it is too small, it is easy to leak the motor. Therefore, do not let the manufacturer arbitrarily change the area of the rammer plate when purchasing;

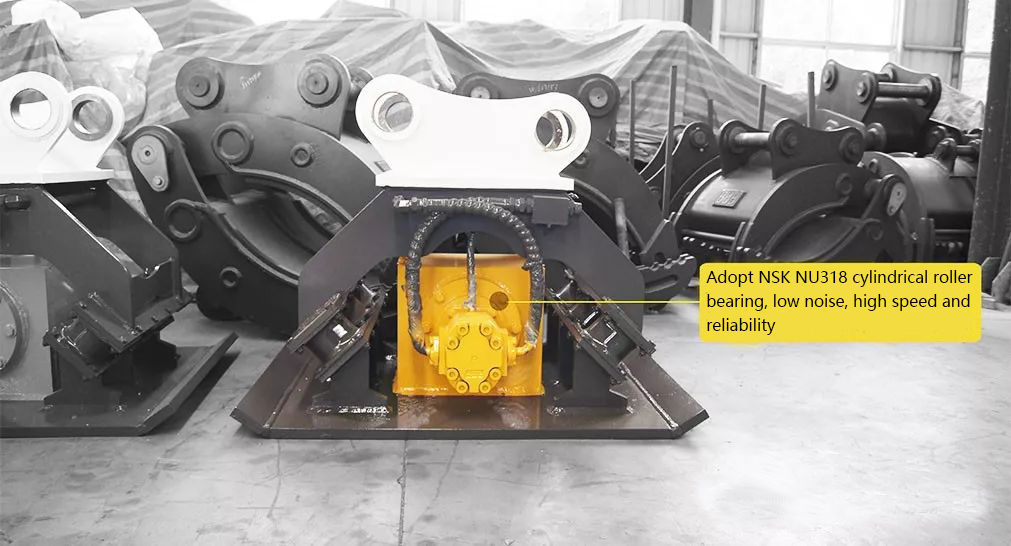

3. Whether the bearings in the main engine are imported, domestically produced centrifugal force is prone to cause the balls to break and fall;

4. The assembly and processing accuracy, there is an eccentric wheel in the vibration compactor host, the rotation of the eccentric wheel must ensure that the concentricity is not greater than 0.001 mm, otherwise it is easy to get stuck and not work;

5. The oil seal must be imported. The rotation of the eccentric wheel during operation can easily lead to an increase in the temperature of the coolant. Oil seals with poor quality are prone to premature aging and oil leakage;

6. Whether the main engine has a control valve (commonly known as overflow valve), the key role of this valve is to protect the motor and overload protection. In addition, the customer feels that the force is too large or too small, and can be mobilized at will.